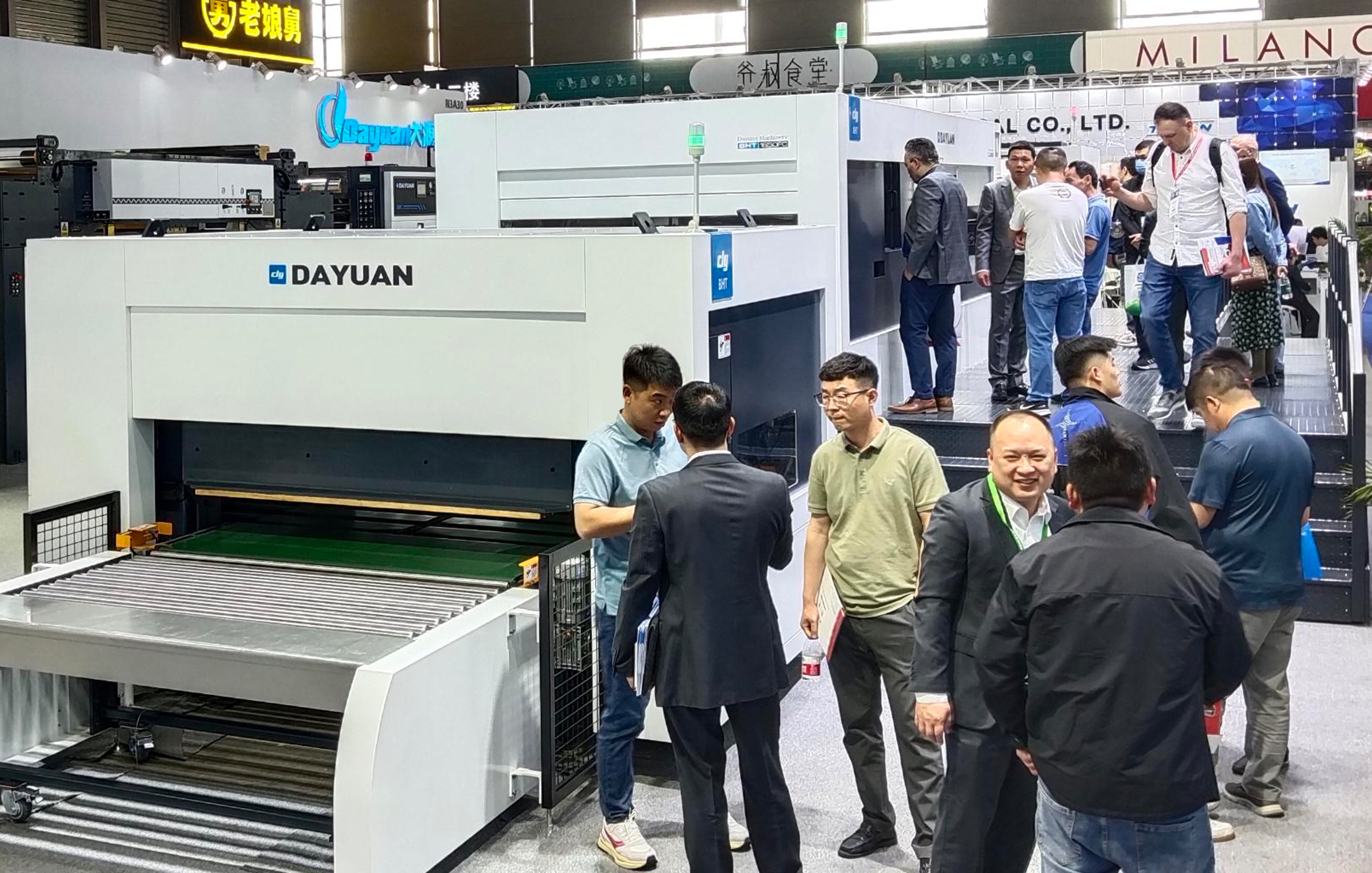

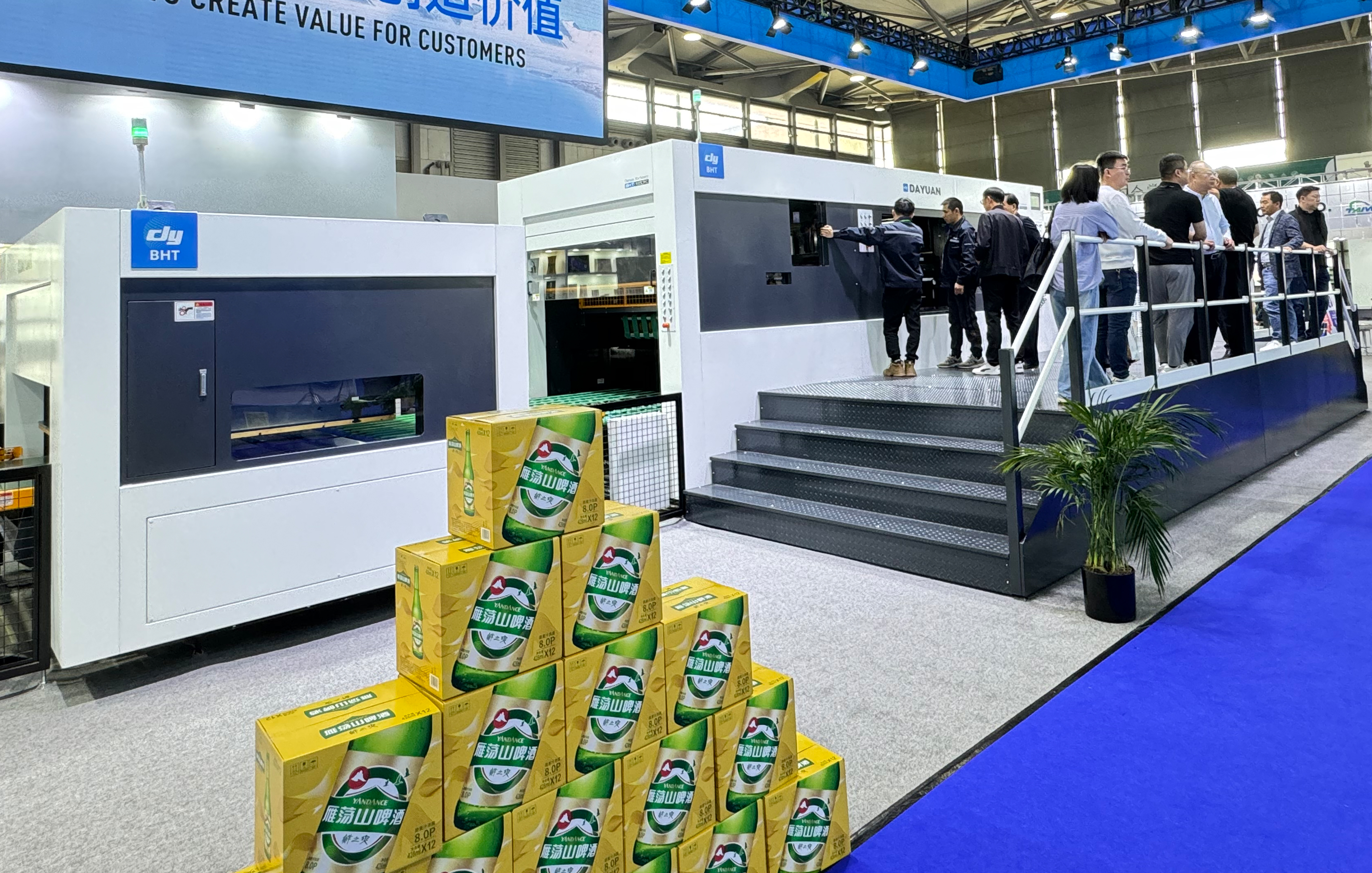

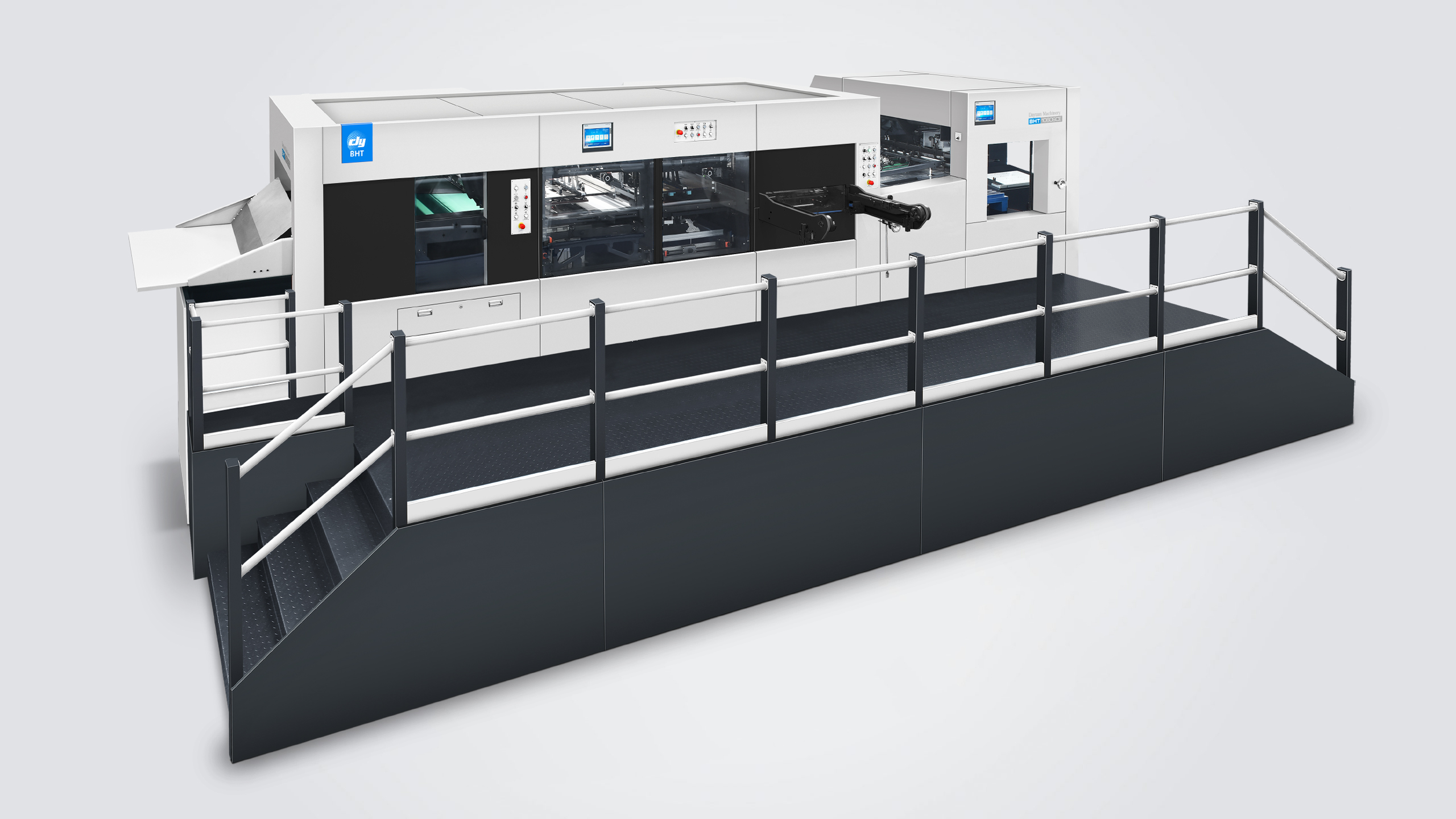

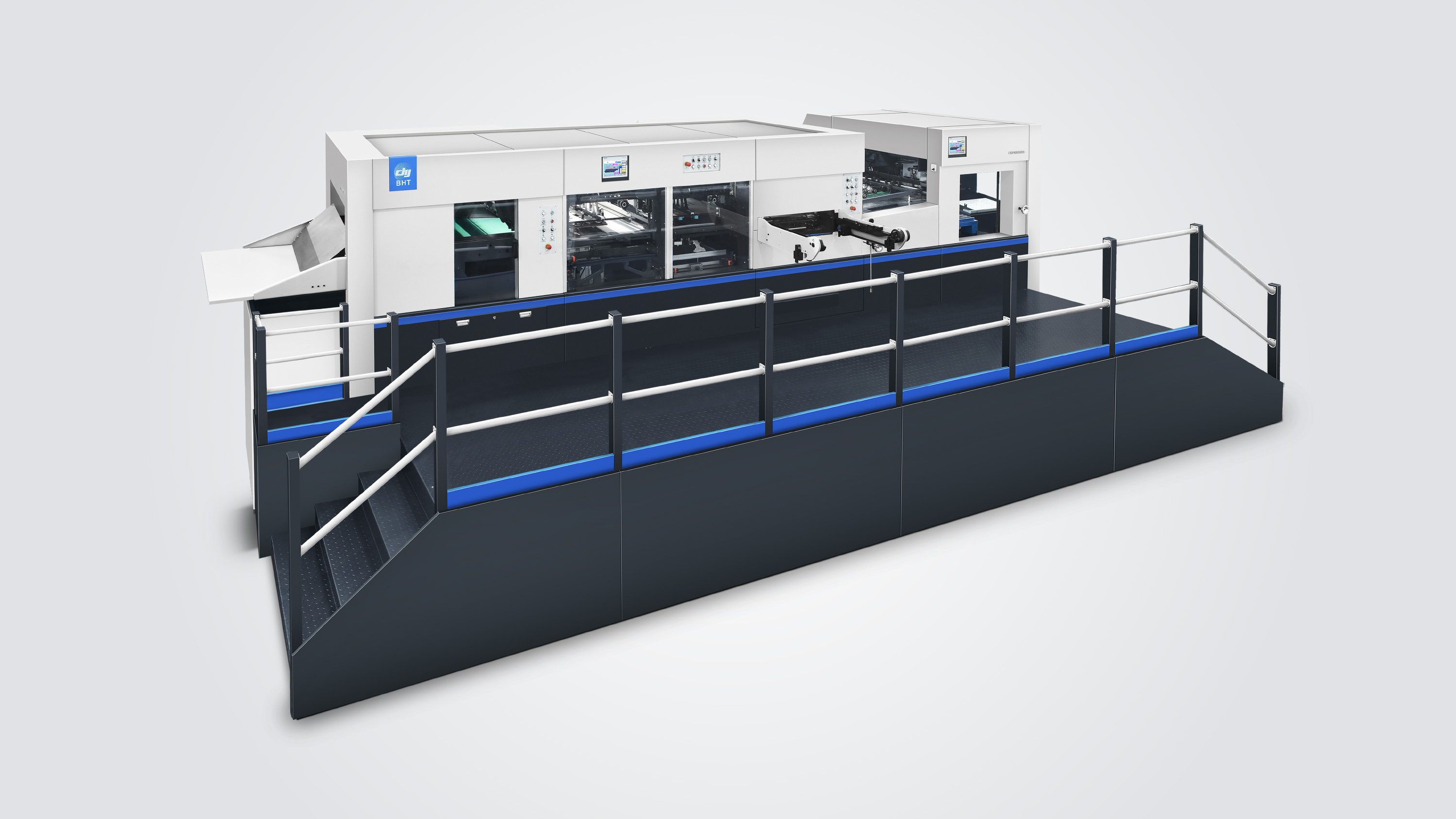

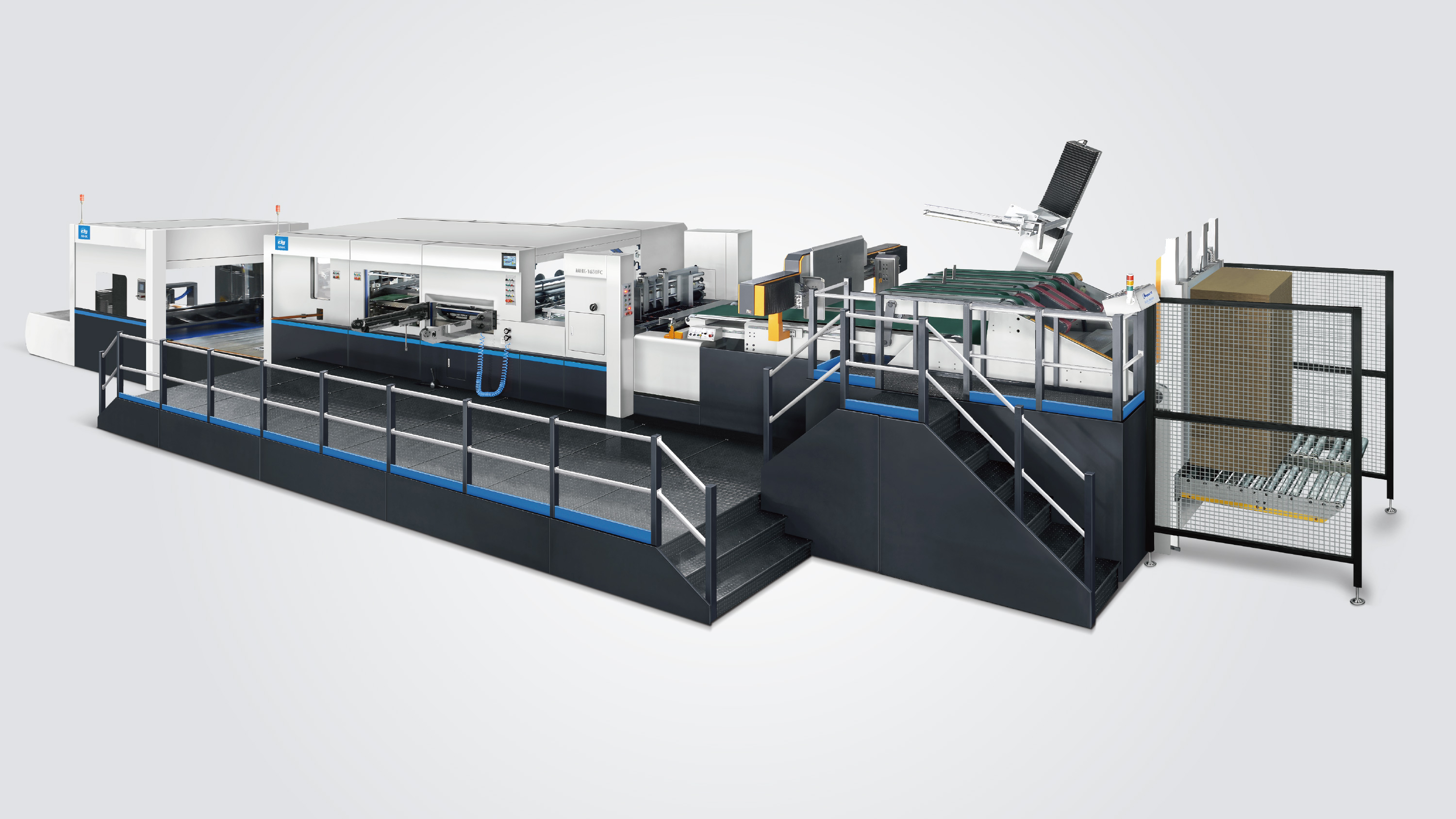

BHT-1650FC?Automatic Die Cutting Machine Linkage Production Line?was the star product of this exhibition. Linkage Production Line can be customized to meet different customer requirements and product processes, supporting personalized configurations and the integration of upstream and downstream production lines. Compared to traditional standalone machines, the integrated line significantly boosts production capacity and reduces paper waste, directly addressing pain points such as slow mass production and inefficient material consumption.

It is compatible with corrugated paper ≤8.5mm thick, including E, B, C, A, and AB flute types, meeting export-grade packaging strength requirements for multi-panel beer cartons and similar products.

The flexible combination of a?push-type automatic paper feeder + die-cutting unit + stripping?unit + multi-functional automatic sheet breaker?integrates multiple standalone machines into a comprehensive, seamlessly connected production line, eliminating unnecessary material handling.

The accompanying?paper breaker?provides an intelligent solution for sorting multi-panel stacks and post-die-cutting processing. It achieves?both vertical and horizontal separation in a single pass, eliminating the need for reorientation and delivering flexible, high-efficiency performance to meet customized production demands.

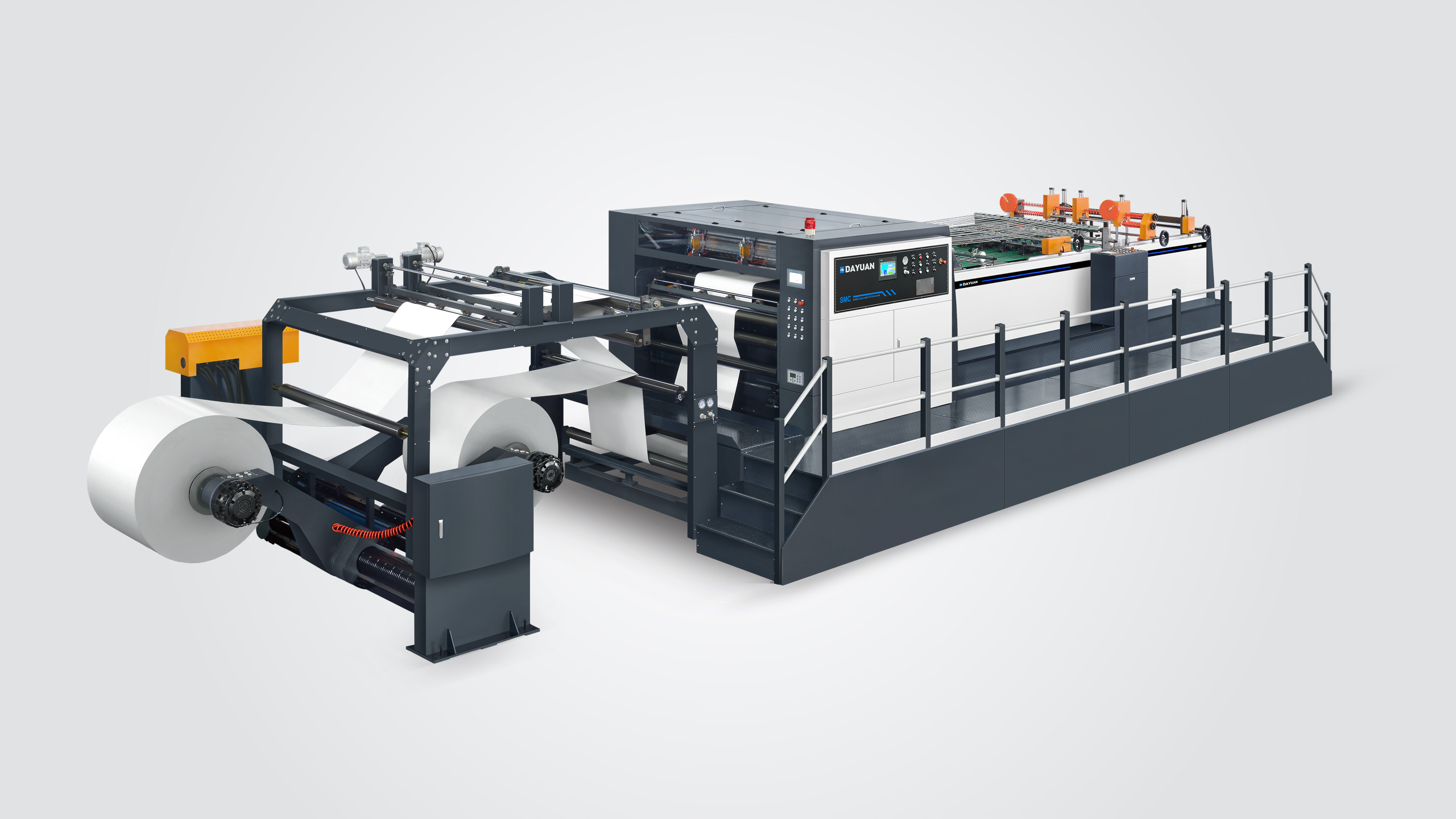

SMC-1500ZH?Servo Precision Double Helix High Speed Sheet Cutter – Our Flagship Equipment at This Exhibition

With?one-key?startup, SMC-1500ZH achieves?fully automated centralized alignment, delivering seamless operation with?non-stop paper splicing, automatic curl correction, edge adjustment, longitudinal cutting, slitting, stacking, and tray switching—all at a?maximum speed of 540 cuts per minute.

Featuring?vacuum suction transport, it ensures?scratch-free and dent-free paper surfaces, guaranteeing?premium product quality. This system is designed to meet the demands of?high-volume production, maximizing efficiency while maintaining precision.

The MHK-1180EFC Automatic Die Cutting & Creasing Machine with Stripping (Down Feeder) is a brand-new equipment launched by Dayuan this year for the milk packaging market in combination with market research. The maximum paper format is 1180x1050mm. The equipment adopts the industry-leading paper feeding technology with a down feeder, which significantly reduces the requirements for paper flatness. At the same time, it ensures zero damage to the paper surface and is perfectly suitable for E, B, C, A and AB corrugated papers with a thickness of ≤8.5mm.

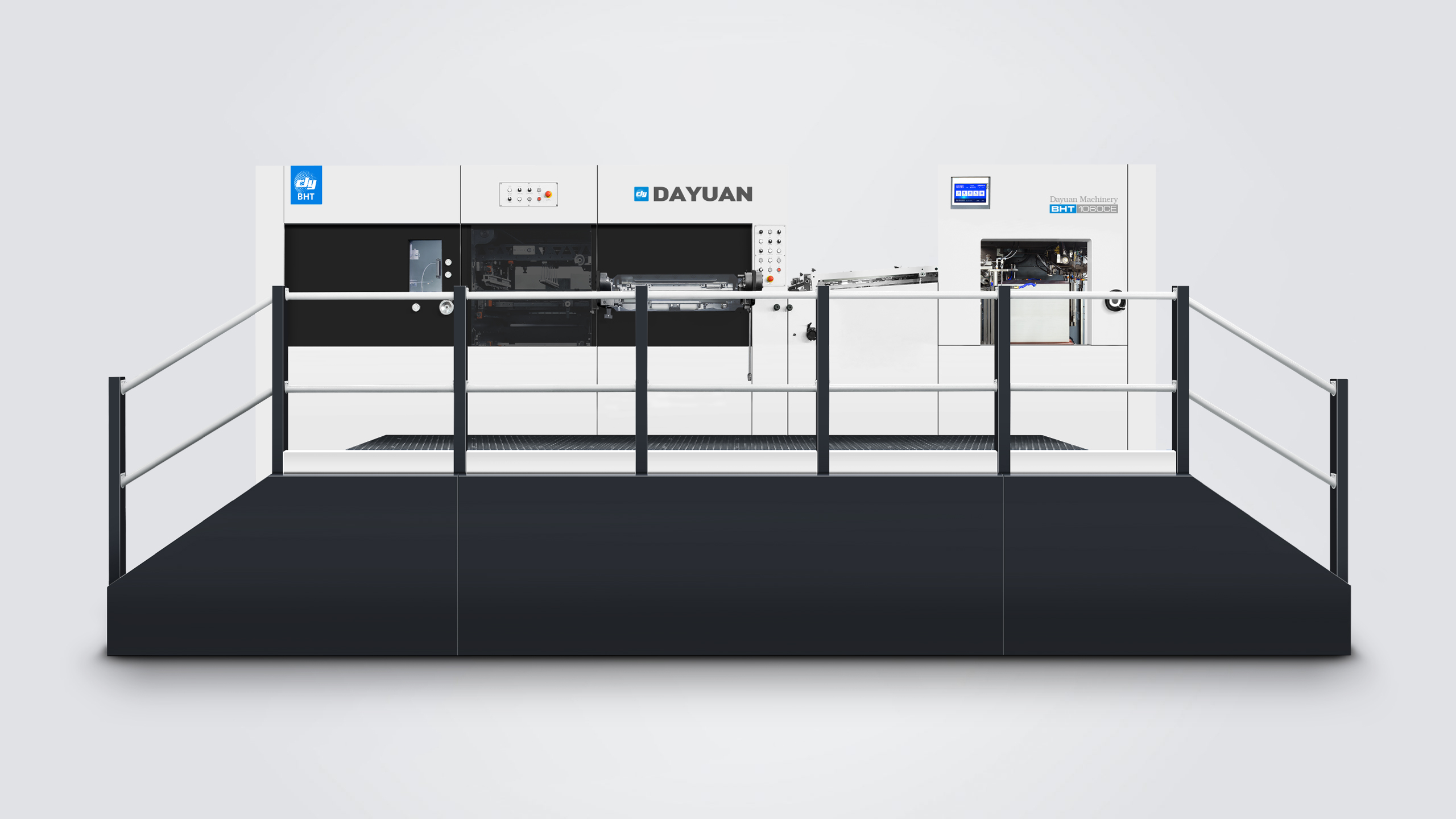

In addition, the exhibited BHT-1060CE?Automatic Die Cutting & Creasing Machine with Stripping?is specifically designed to meet the needs of high-efficiency die cutting and waste removal, with a maximum speed of up to 9,000 sheets per hour.

It is equipped with a feeder featuring four suction and six feeding functions and an ultrasonic double-sheet detection device, which effectively avoids problems such as double sheets and paper jams. The die cutting section applies the turbine variable speed transmission technology, enabling the moving platform to operate precisely at variable speeds, effectively reducing the defects of continuous dots and improving the die cutting quality. It is equipped with a quick fine-tuning plate frame and a fine-tuning cutting?plate, directly reducing the plate adjustment time by 50%. The gripper bar is made of flexible and durable carbon fiber material with small gripper nozzles.

The stripping?section is equipped with a waste removal system with three frames and four sides. The upper and lower frames operate while the middle frame remains stationary to prevent the phenomenon of loose plates. The paper receiving section adopts the design of a non-stop curtain secondary paper receiving device, enabling continuous paper receiving without stopping the machine.

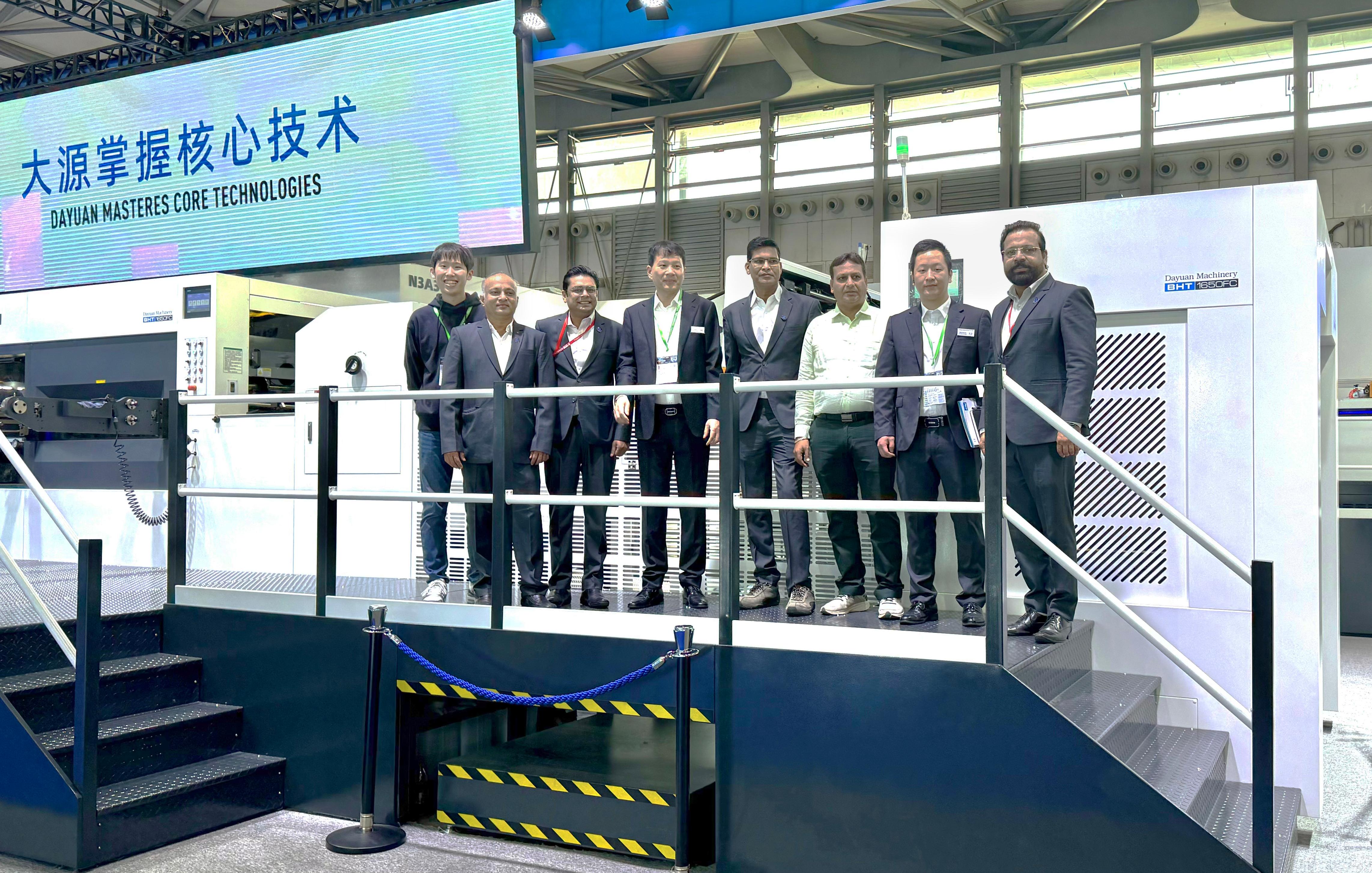

Dayuan focuses deeply on the research and development of core technologies. Relying on world-leading hot stamping, die cutting and paper cutting?equipment, it has occupied a leading position in the packaging equipment manufacturing industry. We sincerely hope that users can witness our excellent performance at the 2025 WEPACK World Packaging Industry Expo, and let the world get to know “DAYUAN”.

In the future, Dayuan will continue to deeply cultivate intelligent manufacturing, create value for customers, and embark on a new journey together with the industry. Dayuan looks forward to jointly writing a new chapter in the printing and packaging industry with global partners and helping the industry achieve intelligent transformation and upgrading.

Our booth is located at W2-007.

CHINA PRINT 2025, a premier international printing exhibition of global scale and scope, has drawn significant attention from the printing industry worldwide. As a pioneer in the printing and packaging industry, Dayuan views this event not merely as a stage to unveil technological advancements, but also as a pivotal platform for fostering industry-wide dialogue and strategic collaboration. We are presenting six globally leading hot stamping, die-cutting, and sheet cutting machines, with live demonstrations of packaging solutions for cigarette packs, liquor boxes, dairy cartons, and more.

- MHK-3S920TTT? ?TRIOPRESS Automatic High Speed Triple Hot Stamping & Die Cutting Machine:

Deeply customized for the cigarette packaging industry, MHK-3S920TTT achieves holographic hot stamping, multi-layer hot stamping, deep embossing, and various complex processes in a single pass. Featuring independently developed hot stamping control systems and foil feeding systems, it delivers a maximum speed of up to 6,200 sheets per hour. Even at high-speed operation, it ensures precision machining and consistent quality for every cigarette pack.

- MHK-2S1050RMC? ?DUOPRESS Automatic High Speed Die Cutting Machine with Heating System:

MHK-2S1050RMC performs?multiple complex processes in a single pass?with a?maximum speed of 7,200 sheets/hour. Each unit is?servo-driven, allowing?flexible process combinations—operate the entire production line or select?individual units?as needed. The?PLC touchscreen control panel?ensures intuitive operation and precise adjustments.?Featuring a?micro-adjustable plate frame and cutting plate, the system enables?rapid and accurate setup, significantly reducing plate change over?time while maintaining?high-speed precision and production efficiency.

- BHT-1060SCE? ?Automatic Die Cutting And Creasing Machine With Stripping & Blanking :

Maximum Speed 8000 sheets/hour. BHT-1060SCE?integrates?die-cutting, waste stripping, and blanking(product separation) in one paper feed, reducing?manual intervention?in post-processing?and?enhancing production efficiency. Turbo-variable transmission technology?in die-cutting unit ensures precise dynamic platform movement.

- MHK-1500AT? ?Automatic Hot Foil Stamping & Die Cutting Machine(Heavy Duty):

MHK-1500AT?is designed for?large-format foil stamping & deep embossing applications with heavy-duty 600-ton press capacity and maximum speed 600 sheets/h. Advanced technology like self-developed foil stamping control system, precision servo-controlled gripper rear positioning system and automatic lubrication supply/cooling system significantly boosts output while ensuring quality.

- MHK-1180CE? ?Automatic Stripping Die Cutting & Creasing Machine:

MHK-1180CE?is designed for high-efficiency die-cutting & waste stripping for milk cartons, luxury handbags & premium packaging. It can achieve non-stop paper collecting with roll-up type auxiliary take-up stand.

Max speed: 7,000 sheets/hour

Stock Range: 100-2000g/m2cardboard, 0.1-2mm cardboard, ≤4mm corrugated board.

- ?SMC-1500ZH? ?Servo Precision Double Helix High Speed Sheet Cutter Machine With Auto Splicer & Auto Pallet Changer:

With one-touch start, the machine achieves automatic centralized alignment of all parts, enabling features such as non-stop paper splicing, automatic reverse bending, edge correction, longitudinal cutting, slitting, paper collection, and non-stop tray changing. It reaches a maximum speed of 540 cuts per minute and utilizes vacuum adsorption for paper transport, ensuring no scratches or impact marks on the paper surface—delivering exceptional product quality for users

We warmly welcome all buyers to engage with us and share your innovative ideas during the use of our equipment. During the exhibition, our team will conduct live demonstrations to showcase the outstanding performance of our machines through real-time operation. We look forward to direct communication with customers, offering more personalized solutions to drive the printing and packaging industry’s transition from traditional manufacturing to smart manufacturing—achieving a dual leap in both production efficiency and product quality.

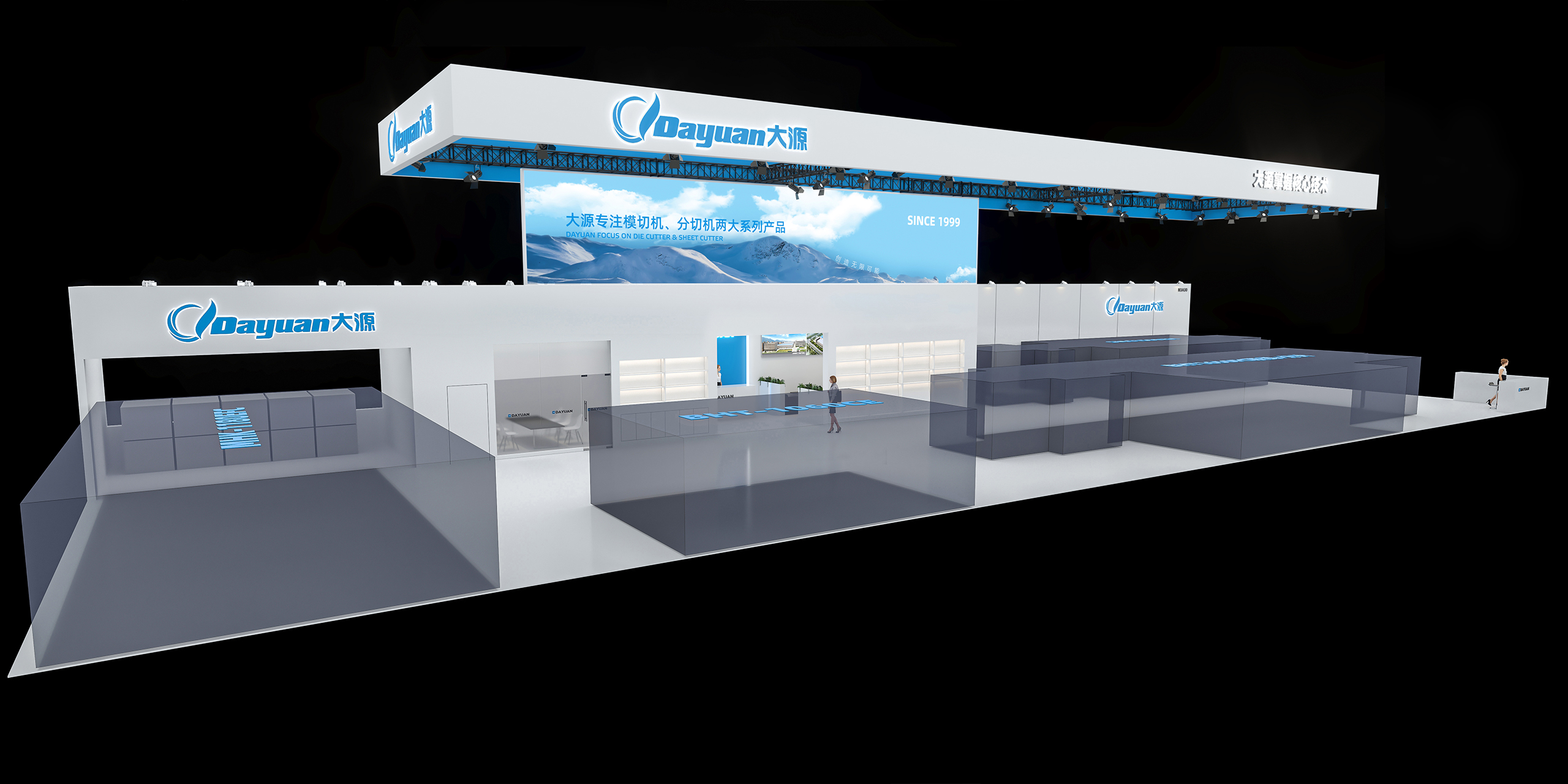

]]>Venue: Shanghai New International Expo Center

Booth Number: N3A30

Machines on Exhibition:

1. Automatic Die Cutting & Creasing Machine With Stripping (Down Feeder) MHK-1180EFC

2.Automatic Stripping Die Cutting & Creasing Machine BHT-1060CE

3.Automatic Die Cutting Machine Linkage Production Line BHT-1650FC

4.Servo Precision Double Helix High Speed Sheet Cutter Machine With Auto Splicer & Auto Pallet Changer SMC-1500ZH

? ? ? ? 在為期五天的展會現場,大源共展出了4臺全新升級的設備,包括MHK-3S1050TTRC多機組叁工位高速自動雙燙金熱壓清廢模切機(全球首發)、MHK-1650FC全自動帶清廢平壓平模切機聯動生產線、SMC-1500ZH自動接紙不停機換托盤雙螺旋卷筒紙分切機、BHT-1060SCE全自動平壓平模切全清廢分品機等。

? ? ? ? 本次展出為大源“大智未來、源于至簡”的品牌形象展,其中MHK-3S1050TTRC多機組叁工位高速自動雙燙金熱壓清廢模切機屬于全球首發,具有一定的轉折意義。大源也成為國內第一家生產多機組叁工位雙燙金且帶清廢功能模切機的供應廠商,這也代表了大源“智造未來”的決心與信心。

21年來,大源一直致力于高新技術的研發與產品的生產,不斷引進國外先進的技術與設備,并通過與法國施耐德公司及德國西門子公司在工控系統上的全面戰略合作,全力打造具國際領先技術水平的新一代高效印前、印后設備。展會現場,大源還推出了MHK-1650FC全自動帶清廢平壓平模切機聯動生產線。

SMC系列自動接紙不停機換托盤雙螺旋卷筒紙分切機,則是大源最新研發的全自動化分切設備。是在SMC系列雙螺旋卷筒紙分切機的基礎上增加了全自動接紙和不停機換托盤的功能,實現了全自動化操作。2019年底,浙江大源進軍數字印刷配套裝備的研發制造領域,重磅推出大源SMC數碼噴墨雙螺旋卷筒紙分切機,推出后即刻獲得了較高的關注和不俗的表現。

? ? ? ? ?到如今,公司擁有“大源”與“瑞陽”兩大品牌,其中集光、機電、液、氣為一體的大源品牌高精密卷筒紙分切機系列產品,和平壓平模切機系列都連續9年銷售量高速增長。

未來,在蔡錦者眼里,大源的發展將面向全球市場,圍繞客戶需求和市場趨勢,將投入更多研發精力,在模切機、分切機領域不斷深化研發、技術沉淀,打造“中國大源”,讓大源成為全球模切機制造工廠。

? ? ? ? 制造最好的設備為客戶創造價值

]]>